I’ve known Georg Palmer since the early ‘80s and I’ve watched (and sometimes taken part in) her journey as a fiber artist. When she first learned to weave, she was making rag rugs, coverlets and throw pillows–and selling them at craft fairs. As she became more proficient at weaving, she started designing and making vests, jackets, coats and accessories and taking part in more prestigious shows.

Her goals were to make beautiful pieces that people would wear for years and to earn enough to make it a profitable venture for herself.

Over the years, Georg has experimented with ancillary crafts to make her pieces more unique and more desirable. She began finishing her pieces with crocheted cuffs and edges but segued to using the knitting machine for her trim. She became proficient with Fimo clay and has made her own buttons to compliment her jackets for years.

Over the last decade, Georg has moved away from weaving because, as she says, “my body was wearing out.” She began designing clothing on the knitting machine and branching out to other forms of art clothing.

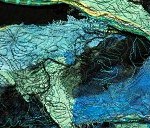

Collage is her current passion and her collage scarves are beautiful.

JF: How long have you been selling the collage scarves?

GP: I’ve been doing them for at least six years. I was investigating ways of using my weaving scraps. For many years, I would take my scraps to shows with me and give or sell them to other fiber artists. They were always happy to get them, but were secretive about what they did with them. I saw some of my scraps incorporated in other peoples work, but they refused to tell me how they did it.

Finally, a fellow artist asked if she could copy my scarf rack. I said she could if she would tell me how she combined my scraps. The secret was water soluble stabilizer. I found a source for it on the internet, ordered it and started experimenting. This was probably 6 years ago.

My first efforts were with my weaving scraps and leftover yarn. I soon learned that I had to sandwich the scraps between two pieces of the stabilizer. Then I would use the sewing machine to sew it all together. I would go backward and forward, seemingly forever, to make sure the scraps would stay together. I probably trashed my sewing machine by doing it that way. I called these first pieces my ‘garbage scarves.’ They were a bit rustic, but I did sell them.

The problem with them is that they were a little too rustic and sometimes a bit heavy for around the neck.

About this time, I signed on for a working vacation. A Wearable Art Cruise to Alaska. Yes, we had classes every day and saw the wonders of Alaska.

During this cruise, I learned about free motion sewing. I also began doing collage with mostly commercial fabrics. I was inspired to refine my ‘garbage scarves’ into ‘collage scarves.’

JF: What are your collage scarves like now?

GP: Currently I’m using mostly silk scraps that I buy in bulk and then over dye to get variations of one color. I used to leave spaces between the fabrics. With the silks I tend to overlap them in an organic way–no straight lines. I also fringe all the pieces before sewing them together. The scarves are very airy and drape well.

JF: What else are you doing with collage?

GP: I’m also doing some vests. Right now they have collaged backs and solid fronts with details done in the collage technique. They are still evolving.

JY: Can you share how to make a collage scarf?

GP: Sure. You need to buy some Super Solvey. Solvey comes in three weights. Super Solvey is the middle weight. Buy enough to have a two pieces the size of your scarf or project.

Lay out your design on one piece,cover it, secure it firmly with pins and take it to the sewing machine. I use the free motion technique to securely sew the whole sandwich together.

The next step is removing the paper. I take the piece to the sink and run hot water over it while filling the basin. I let it soak until the water feels gelatinous. I then drain the sink and rinse the piece in hot water and let it soak in the hot water bath with a little bit of Dawn detergent added. This should take out all the paper. Rinse again, hang it to dry and the scarf is finished and ready to wear. If the scarf needs some body after washing, it can be sprayed lightly with spray starch.

Georg works out of her home studio in Alamo and markets under the name of By George. She will have a booth March 9 & 10 at Fort Mason in the Contemporary Craft Show.

Click here for the next article.